Vertical Contact Technology

ICT’s Vertical Contact Technology (VCT) uses an extremely reliable technology to probe aluminum and copper pads as well as solder bumps of all types. VCT has several impressive advantages. It is perfect for multi-die and full array applications. VCT can use a matched impedance space transformer for high frequency signal routing, and special RF versions are available for use up to 10 GHz.

The temperature range of VCT is equally impressive, and a single device (if so specified) may be used in a temperature range of – 40° to +175° C. In addition to being much less impacted by temperature, the probe remains in place as overdrive is applied thereby minimizing probe mark and pad damage.

Use of VCT to probe multi-die simultaneously can significantly save tester time and cost, with major benefits in total cost of ownership.

Features:

- Robust – based on a well proven technology

- Temperature – can be designed to operate over a huge temperature range

- Cost Savings – multi-die capability can dramatically reduce total test costs

- Yield Increases – proven Yield Increases for VCT over cantilever probes

- Probe mark – minimal compared to pad damage from cantilever probes

Space Transformation:

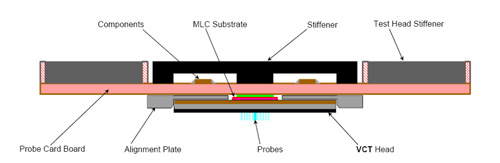

ICT’s VCT probe assemblies transfer the device signals and power connections to the probe card through the “space transformer”. These can be simple, hard wired connections, or matched impedance, high frequency interposers using MLC’s or MLO’s . ICT also supplies space transformers which direct connect to the PCB where applicable.

Solder Bumps and Peripheral Aluminum/Copper Pads:

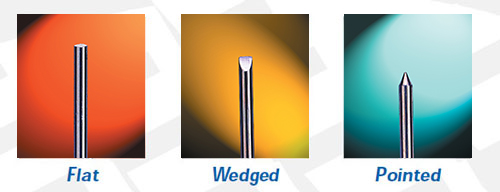

Devices with solder bumps of all types are probed with standard, flat tipped probes. The probe size used is dependent on bump pitch. Matrix formations of 10,000 probes and more are routinely accommodated.

Aluminum and copper pads are vertically probed with pointed tips to ensure good contact and low resistance. Matrix formations of pads, peripheral rows, or multi-die formations of pads can be probed using VCT pointed tips.

Turnkey Solutions:

ICT offers turnkey solutions across multiple test platforms. We design and fabricate the PCB as well as the MLC/MLO. ICT attaches the substrate to the PCB and designs all associated VCT hardware to complete the space transformer and allow for interchangeability of probe heads. These solutions are designed to meet all customer specifications.

ICT Advantage:

Our focus on quality and customer service provides our customers a high level of security that an excellent product will be delivered in the shortest lead time. We pride ourselves on our product working “out of the box” time after time. There are many options in using VCT to optimize your test department’s output and in minimizing your total costs.